Upgrading the PROVerXL 4030 with a Katsu Router

I'm a big fan of my Genmitsu PROVerXl 4030, but the spindle that's bundled with the machine has its limits. Since I'm impatient, I was thinking about upgrading to another Router for a while – and finally did it.

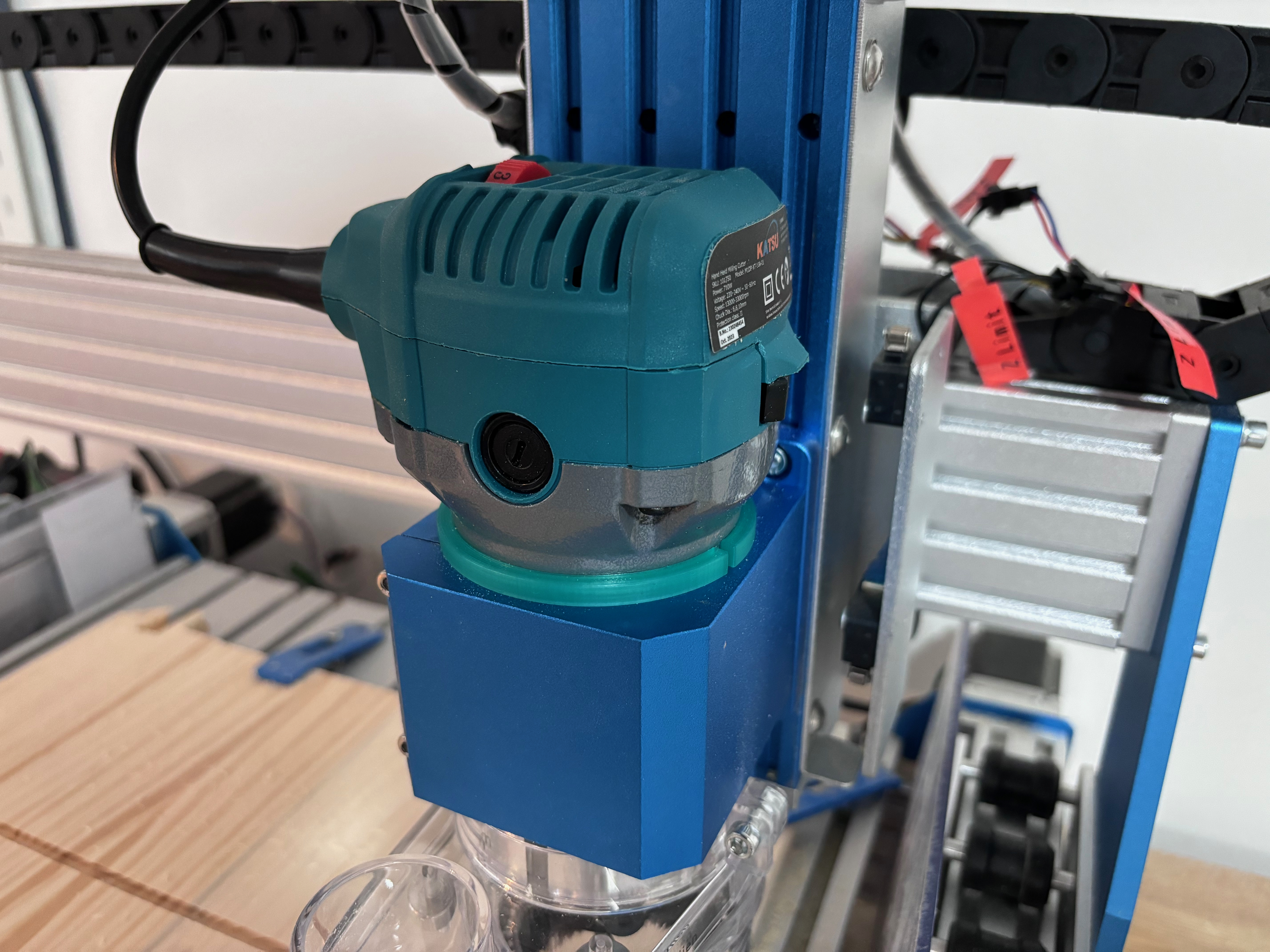

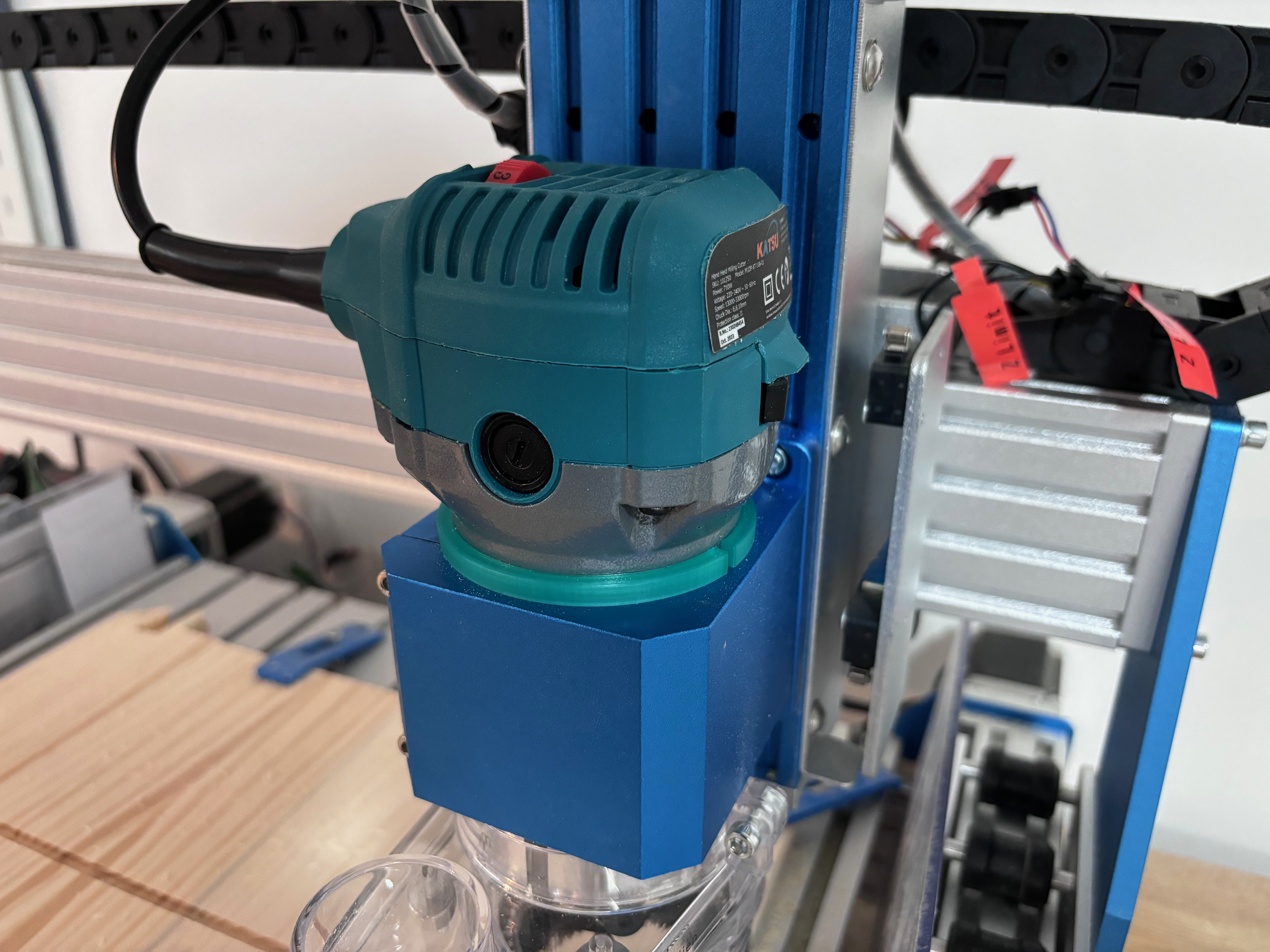

At a roughly 60€ price point, the Katsu Router itself is a no brainer. Since it's the knock-off version of another brand, even the color scheme feels weirdly familiar. I had to design and print a small adaptor ring to make it fit with the provided DeWalt-Adaptor, but after that, you can jump right into it. Here's how to whole assembly looks with the new mount, the adaptor ring and the router in place.

One note here: I think Katsu is the European brand name for selling those, from what I've learned, a very similar item is branded as Vevor in the US. They look alike, but for this post, I've only tried the Katsu one.

My very first observation was that you need a different kind of dust extraction with that thing – even at speed setting 2 or 3 it's finding dust that you never knew was there in the first place – and then throwing it halfway across the room. The dust shoes for the old spindle obviously don't fit, and the ones offered by Genmitsu are out of stock in Europe, so you have to go with the Fox Alien ones, but they fit just as well. The assembly itself is in itself less robust, the shadow line between the two parts that are held together by magnets is doing a poor job of helping with mating the two halves. But once its in place, it works well.

The next observation or rather acknowledgement was: the collet sizes are super different. While the Genmitsu spindle is an ER11 collet that is factory fitted with a 1/4 inch bit, the Katsu comes with three collets – 6, 8 and 10mm. In the end, you'll need new tools. I've started with a 6mm flat downcut endmill, while also ordering a (compatible) 1/4" Makita collet.

One of the biggest differences is certainly that the Katsu is plugged in to a power socket directly, meaning you have to turn it on and off whenever a job starts. That's acceptable for roughly the first 5 times using it. I figured that it's just a matter of time until I forget to turn it on, and given the price of proper tools, plunging an end mill into a workpiece because I forgot to turn on the router feels like a stupid way to waste money – so I need a simple solution that switches the router on whenever the spindle would have been turned on.

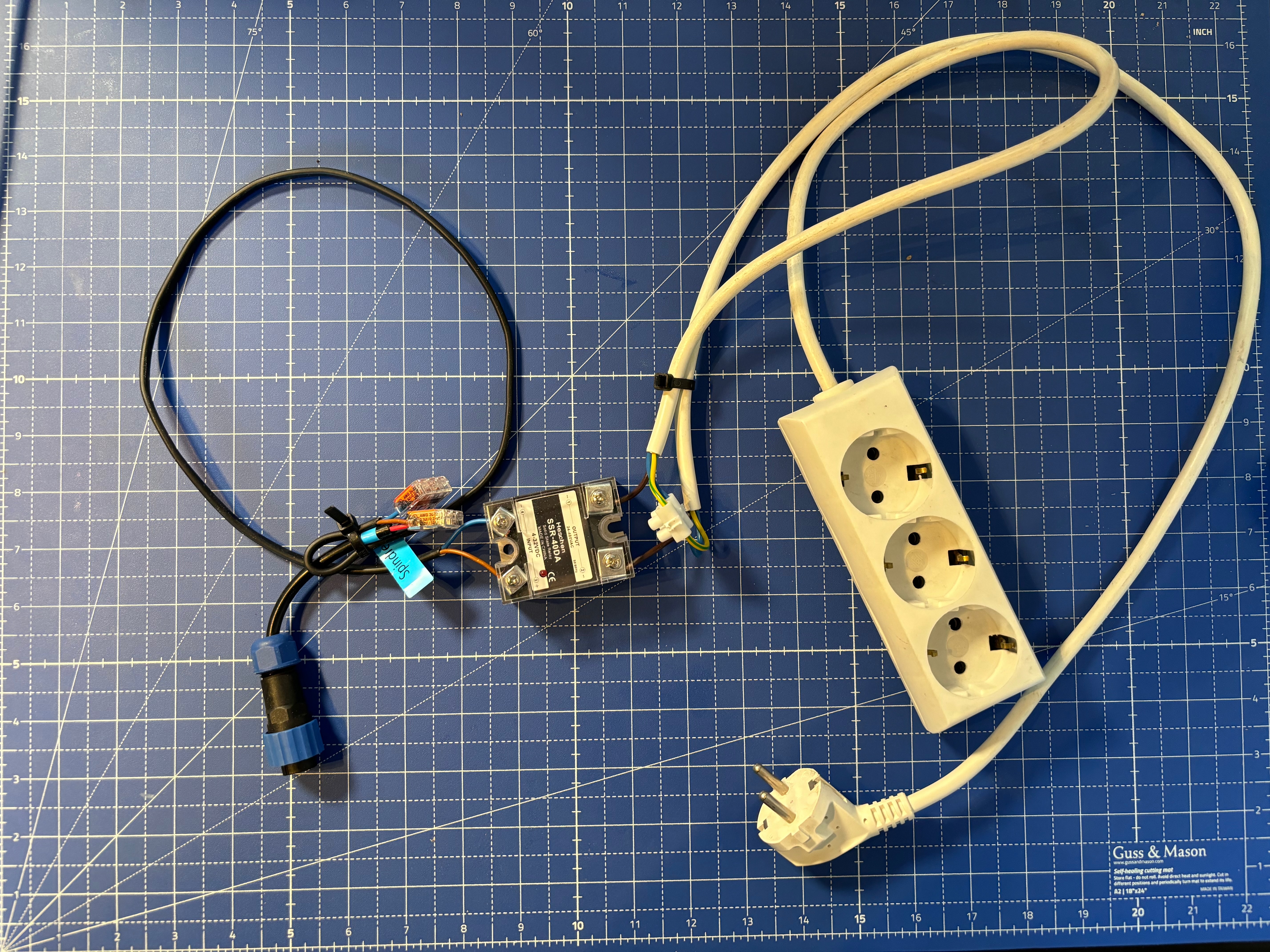

A relay. I need a relay. A relay is a switch that uses an electric signal to open or close a circuit. Since the current to drive the factory provided spindle is somewhere in the 0-48V Range (depending on the RPM setting on the controller), getting a Relay that is able to switch regular 230V using a switching current that supports the input range is simple – I settled on one for around 10€ that is able to deal with up to 40 amps on the switched circuit. A note here: I choose one that can deal with up to 32V on the switching current and turned down the RPM, which did the trick. Note: only build something like this if you're aware of the dangers and risks inherent to working with electricity – if you replicate this, it's solely at your own risk.

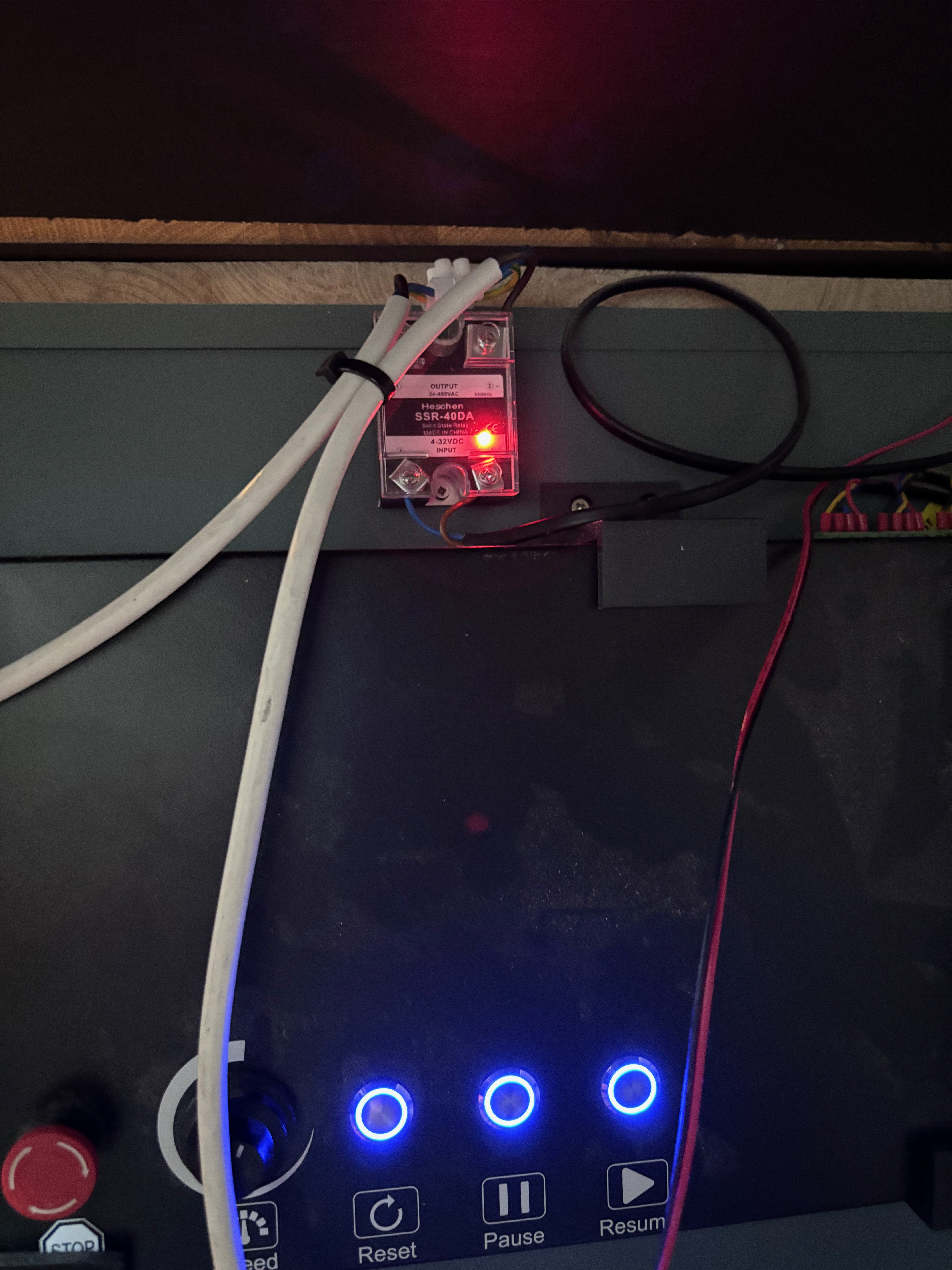

As for the installation, I simply connected the spindle output to the Relay and use it to switch a whole power strip on or off. That way, I can also connect my dust collection – fancy name for a vacuum – and have it turn on automatically whenever a job starts to run.

It works pretty flawlessy, and there's even a lovely red indicator light when the relay is switching. For the setup, I turned on only the spindle and dialed the RPM on the Genmitsu control panel up until the Relay switched – I figured that's the minimum current that works for this application. I ran a 45 minute job with both a Vacuum and the router running, and while the relay itself got warm, it never got hot.

With all of that in place, I have to say the performance upgrade is quite something – I can easily work at like 3x-4x the speeds I did previously, and the machine isn't remotely running at its full capacity. There's also something to be said about the sturdiness of the build of the 4030 – it's remarkably unimpressed by even deep and fast cuts.

Here's a small list of things that helped me get started (some are affiliate links):

Comments